- Due to continuous improvement, specifications are subject to change without prior notice,

- Plasticizing capacity is based on the standard test conditions performed by SUPERMAC MACHINERY

- Injection mass, injection ratio and plasticizing capacity differ depending on the resin used & molding condition.

- Kindly contact us to discuss using machine at the maximum capacity.

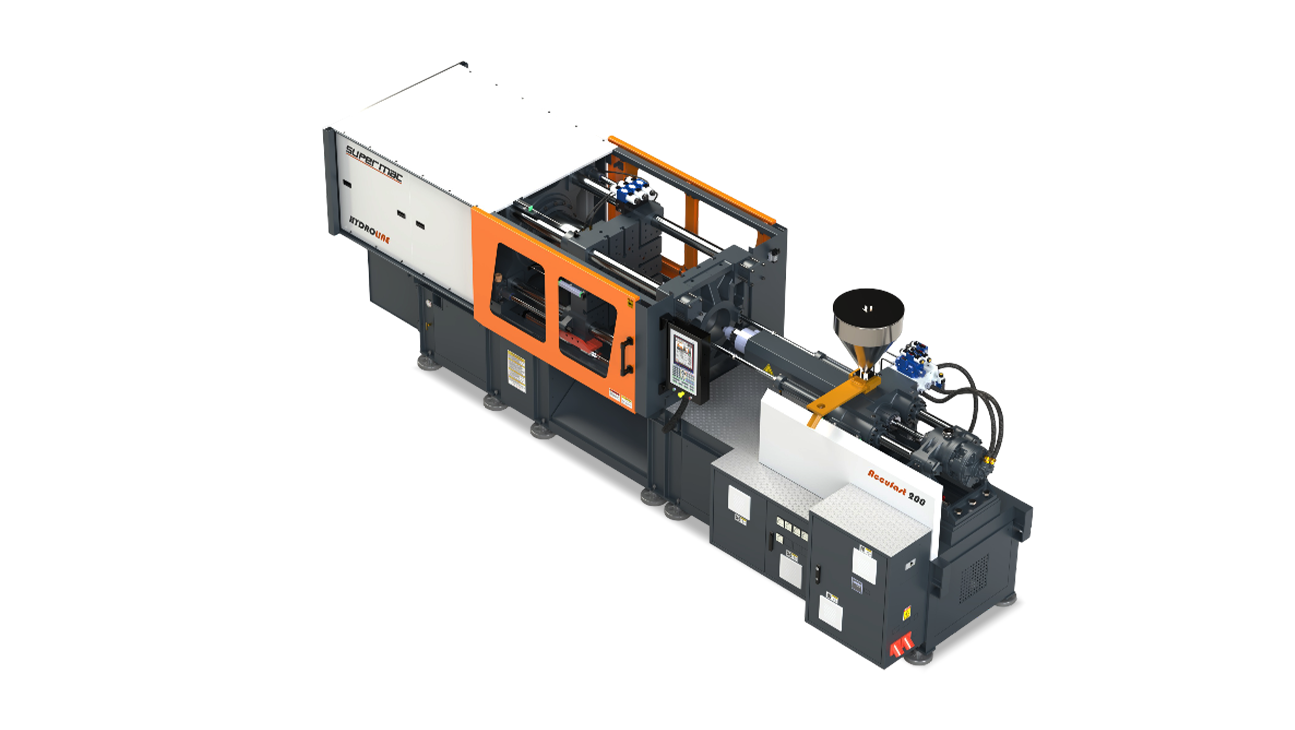

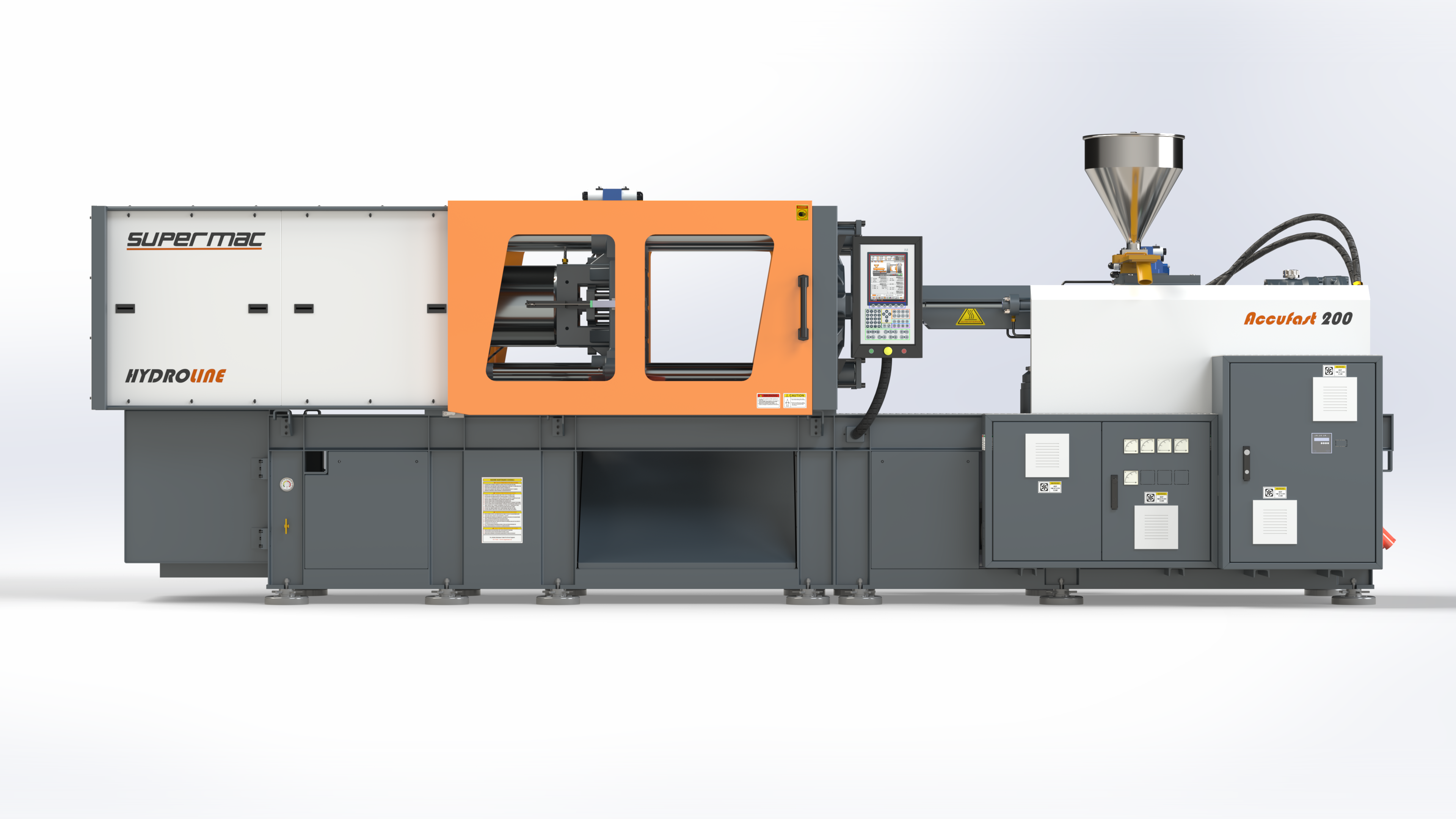

Hydroline Accufast

Hydroline Accufast

Specification

| MODEL | UNIT | ACCUFAST 80 |

|---|---|---|

| INJECTION UNIT SPECIFICATION | ||

| Screw Diameter | mm | 35 |

| Injection Pressure Max | bar | 1715 |

| Theoretical Displacement | cc | 144 |

| Max. Injection Weight (GPPS) | gm | 130 |

| Injection Speed | mm/sec | 240 |

| Plasticizing Capacity | gm/sec | 15 |

| Injection Rate | cc/sec | 230 |

| Injection Screw Stroke | mm | 150 |

| Screw L/D Ratio | L/D | 20 |

| Screw Speed Max | rpm | 430 |

| Heater Capacity | kw | 7 |

| No. of Heating Zones | nos | 3+1 |

| CLAMPING UNIT | ||

| Mould Clamping Force | tons | 80 |

| Maximum Day Light | mm | 650 |

| Minimum Mould Height | mm | 150 |

| Maximum Mould Opening Stroke | mm | 500 |

| Distance Between Tie Rod (H × V) | mm | 380 × 380 |

| Mould Platen Size (H × V) | mm | 570 × 570 |

| Tie Rod Dia | mm | 65 |

| Ejector Force | tons | 3 |

| Ejector Stroke | mm | 100 |

| GENERAL DATA | ||

| Servo Motor | Kw | 15 |

| Oil Tank Capacity | ltrs | 275 |

| Water Requirement (inlet temp.29°C) | lpm | 50 |

| Connected Load | Kw | 22 |

| Machine Weight | tons | 3.5 |

| Machine Dimensions (L × W × H) | ft | 12.8 × 2.6 × 5.1 |

| MODEL | UNIT | ACCUFAST 110 | |

|---|---|---|---|

| INJECTION UNIT SPECIFICATION | A | B | |

| Screw Diameter | mm | 35 | 40 |

| Injection Pressure Max | bar | 1715 | 1750 |

| Theoretical Displacement | cc | 144 | 201 |

| Max. Injection Weight (GPPS) | gm | 130 | 200 |

| Injection Speed | mm/sec | 240 | 210 |

| Plasticizing Capacity | gm/sec | 15 | 22 |

| Injection Rate | cc/sec | 230 | 266 |

| Injection Screw Stroke | mm | 150 | 180 |

| Screw L/D Ratio | L/D | 20 | 20 |

| Screw Speed Max | rpm | 430 | 450 |

| Heater Capacity | kw | 7 | 9 |

| No. of Heating Zones | nos | 3+1 | 3+1 |

| CLAMPING UNIT | |||

| Mould Clamping Force | tons | 110 | |

| Maximum Day Light | mm | 750 | |

| Minimum Mould Height | mm | 200 | |

| Maximum Mould Opening Stroke | mm | 550 | |

| Distance Between Tie Rod (H × V) | mm | 410 × 410 | |

| Mould Platen Size (H × V) | mm | 610 × 610 | |

| Tie Rod Dia | mm | 70 | |

| Ejector Force | tons | 4.5 | |

| Ejector Stroke | mm | 100 | |

| GENERAL DATA | |||

| Servo Motor | Kw | 18 | 23 |

| Oil Tank Capacity | ltrs | 400 | 400 |

| Water Requirement (inlet temp.29°C) | lpm | 50 | 50 |

| Connected Load | Kw | 32 | 32 |

| Machine Weight | tons | 4.5 | |

| Machine Dimensions (L × W × H) | ft | 15 × 3 × 5.5 | |

| MODEL | UNIT | ACCUFAST 125 | |

|---|---|---|---|

| INJECTION UNIT SPECIFICATION | A | B | |

| Screw Diameter | mm | 40 | 45 |

| Injection Pressure Max | bar | 1750 | 1760 |

| Theoretical Displacement | cc | 226 | 286 |

| Max. Injection Weight (GPPS) | gm | 201 | 310 |

| Injection Speed | mm/sec | 210 | 220 |

| Plasticizing Capacity | gm/sec | 22 | 27 |

| Injection Rate | cc/sec | 266 | 337 |

| Injection Screw Stroke | mm | 180 | 215 |

| Screw L/D Ratio | L/D | 20 | 20 |

| Screw Speed Max | rpm | 450 | 450 |

| Heater Capacity | kw | 9 | 13 |

| No. of Heating Zones | nos | 3+1 | 4+1 |

| CLAMPING UNIT | |||

| Mould Clamping Force | tons | 125 | |

| Maximum Day Light | mm | 800 | |

| Minimum Mould Height | mm | 200 | |

| Maximum Mould Opening Stroke | mm | 600 | |

| Distance Between Tie Rod (H × V) | mm | 460 × 460 | |

| Mould Platen Size (H × V) | mm | 720 × 720 | |

| Tie Rod Dia | mm | 80 | |

| Ejector Force | tons | 6 | |

| Ejector Stroke | mm | 140 | |

| GENERAL DATA | |||

| Servo Motor | Kw | 23 | 27 |

| Oil Tank Capacity | ltrs | 450 | 450 |

| Water Requirement (inlet temp.29°C) | lpm | 50 | 50 |

| Connected Load | Kw | 40 | 40 |

| Machine Weight | tons | 5 | |

| Machine Dimensions (L × W × H) | ft | 17.5 × 3.5 × 5.5 | |

| MODEL | UNIT | ACCUFAST 150 | ||

|---|---|---|---|---|

| INJECTION UNIT SPECIFICATION | A | B | C | |

| SCREW DIAMETER | mm | 40 | 45 | 50 |

| INJECTION PRESSURE MAX | bar | 1750 | 1760 | 1850 |

| THEORETICAL DISPLACEMENT | cc | 226 | 342 | 490 |

| MAX. INJECTION WEIGHT (GPPS) | gm | 200 | 310 | 442 |

| INJECTION SPEED | mm/sec | 210 | 220 | 245 |

| PLASTICIZING CAPACITY | gm/sec | 24 | 27 | 43 |

| INJECTION RATE | cc/sec | 266 | 337 | 475 |

| INJECTION SCREW STROKE | mm | 180 | 215 | 250 |

| SCREW L/D RATIO | L/D | 20 | 20 | 22 |

| SCREW SPEED MAX | rpm | 450 | 450 | 450 |

| HEATER CAPACITY | kw | 9 | 13 | 17 |

| NO. OF HEATING ZONES | nos | 3+1 | 3+1 | 4+1 |

| CLAMPING UNIT | ||||

| MOULD CLAMPING FORCE | tons | 150 | ||

| MAXIMUM DAY LIGHT | mm | 850 | ||

| MINIMUM MOULD HEIGHT | mm | 200 | ||

| MAXIMUM MOULD OPENING STROKE | mm | 650 | ||

| DISTANCE BETWEEN TIE ROD (H X V) | mm | 510 x 510 | ||

| MOULD PLATEN SIZE (H X V) | mm | 760 x 760 | ||

| TIE ROD DIA | mm | 90 | ||

| EJECTOR FORCE | tons | 6 | ||

| EJECTOR STROKE | mm | 140 | ||

| GENERAL DATA | ||||

| SERVO MOTOR | Kw | 23 | 27 | 32 |

| OIL TANK CAPACITY | ltrs | 575 | 575 | 575 |

| WATER REQUIREMENT (inlet temp.29c) | lpm | 50 | 50 | 50 |

| CONNECTED LOAD | Kw | 32 | 40 | 49 |

| MACHINE WEIGHT | Tons | 5.7 | ||

| MACHINE DIMENSIONS (L x W x H) | ft | 18 x 3.5 x 6 | ||

| MODEL | UNIT | ACCUFAST 200 | ||

|---|---|---|---|---|

| INJECTION UNIT SPECIFICATION | A | B | C | |

| SCREW DIAMETER | mm | 45 | 50 | 50 |

| INJECTION PRESSURE MAX | bar | 1760 | 1850 | 1850 |

| THEORETICAL DISPLACEMENT | cc | 342 | 417 | 490 |

| MAX. INJECTION WEIGHT (GPPS) | gm | 310 | 424 | 498 |

| INJECTION SPEED | mm/sec | 220 | 245 | 280 |

| PLASTICIZING CAPACITY | gm/sec | 27 | 43 | 53 |

| INJECTION RATE | cc/sec | 337 | 475 | 553 |

| INJECTION SCREW STROKE | mm | 215 | 250 | 250 |

| SCREW L/D RATIO | L/D | 20 | 20 | 22 |

| SCREW SPEED MAX | rpm | 450 | 450 | 450 |

| HEATER CAPACITY | kw | 13 | 17 | 17 |

| NO. OF HEATING ZONES | nos | 3+1 | 4+1 | 4+1 |

| CLAMPING UNIT | ||||

| MOULD CLAMPING FORCE | tons | 200 | ||

| MAXIMUM DAY LIGHT | mm | 1000 | ||

| MINIMUM MOULD HEIGHT | mm | 250 | ||

| MAXIMUM MOULD OPENING STROKE | mm | 750 | ||

| DISTANCE BETWEEN TIE ROD (H X V) | mm | 560 X 560 | ||

| MOULD PLATEN SIZE (H X V) | mm | 830 X 830 | ||

| TIE ROD DIA | mm | 100 | ||

| EJECTOR FORCE | tons | 10 | ||

| EJECTOR STROKE | mm | 170 | ||

| GENERAL DATA | ||||

| SERVO MOTOR | Kw | 27 | 32 | 32 |

| OIL TANK CAPACITY | ltrs | 600 | 600 | 600 |

| WATER REQUIREMENT (inlet temp.29c) | lpm | 75 | 75 | 75 |

| CONNECTED LOAD | Kw | 40 | 49 | 49 |

| MACHINE WEIGHT | Tons | 9 | ||

| MACHINE DIMENSIONS (L x W x H) | ft | 19 X 4 X 6.5 | ||

| MODEL | UNIT | ACCUFAST 200 | ||

|---|---|---|---|---|

| INJECTION UNIT SPECIFICATION | A | B | C | |

| SCREW DIAMETER | mm | 45 | 50 | 50 |

| INJECTION PRESSURE MAX | bar | 1760 | 1850 | 1850 |

| THEORETICAL DISPLACEMENT | cc | 342 | 417 | 490 |

| MAX. INJECTION WEIGHT (GPPS) | gm | 310 | 424 | 498 |

| INJECTION SPEED | mm/sec | 220 | 245 | 280 |

| PLASTICIZING CAPACITY | gm/sec | 27 | 43 | 53 |

| INJECTION RATE | cc/sec | 337 | 475 | 553 |

| INJECTION SCREW STROKE | mm | 215 | 250 | 250 |

| SCREW L/D RATIO | L/D | 20 | 20 | 22 |

| SCREW SPEED MAX | rpm | 450 | 450 | 450 |

| HEATER CAPACITY | kw | 13 | 17 | 17 |

| NO. OF HEATING ZONES | nos | 3+1 | 4+1 | 4+1 |

| CLAMPING UNIT | ||||

| MOULD CLAMPING FORCE | tons | 200 | ||

| MAXIMUM DAY LIGHT | mm | 1000 | ||

| MINIMUM MOULD HEIGHT | mm | 250 | ||

| MAXIMUM MOULD OPENING STROKE | mm | 750 | ||

| DISTANCE BETWEEN TIE ROD (H X V) | mm | 560 X 560 | ||

| MOULD PLATEN SIZE (H X V) | mm | 830 X 830 | ||

| TIE ROD DIA | mm | 100 | ||

| EJECTOR FORCE | tons | 10 | ||

| EJECTOR STROKE | mm | 170 | ||

| GENERAL DATA | ||||

| SERVO MOTOR | Kw | 27 | 32 | 32 |

| OIL TANK CAPACITY | ltrs | 600 | 600 | 600 |

| WATER REQUIREMENT (inlet temp.29c) | lpm | 75 | 75 | |

Standard Features

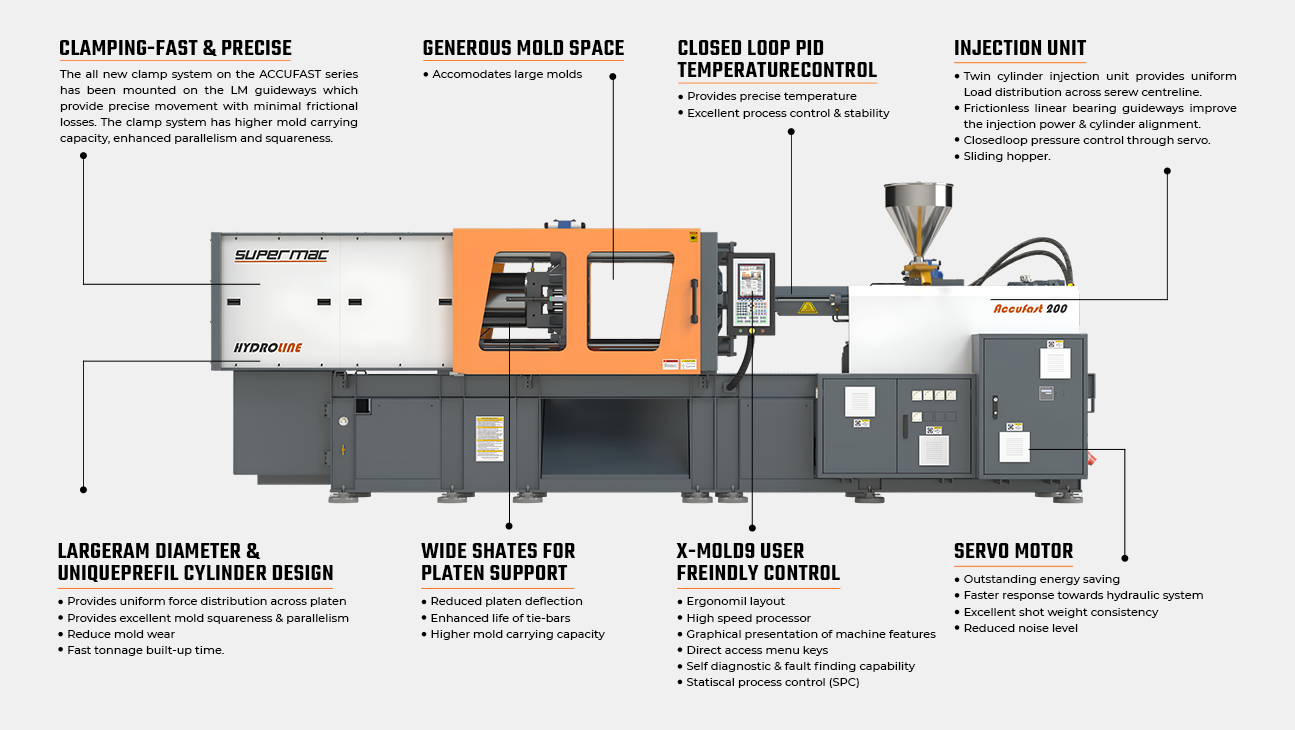

Clamp

- Large prefill designed for fast tonnage build up

- Hollow headless ram with mono seal & no piston rings

- Unique prefill design for fast tonnage build-up

- High speed traverse cylinders

- T-slot platens with tapped holes

- Adjustable moving platen skates

- Rigid casting platens

- Adjustable 5 stage closing and 5 stage opening speed & pressure

- Adjustable 2 stage mold safety pressure & 1 stage speed

- Position based ramping for switching-precise speed & pressure control

- Linear position transducer for precise clamp position control

- Sensitive mold protection with try again circuit

- Stage wise actual time display

- Insert molding programe

- Actual tonnage read pressure transducer

- Actual tonnage display on screen

Hydraulics

- Servo motor driven pump

- Convenient hydraulic layout for easy approach

- Valves placed near actuators for quick response

- Low oil level indicator

- Continuous oil filtration with 10 micron filter

- Oil temperature on screen

Available Options

- Proportional speed control for mold open & close

- Proportional back pressure control on screen

- Air ejection

- Hydraulic core pull

- Feed throat temperature control

- Part drop sensor for single cavity

- Water manifolds

- Robot interface (EUROMAP 67)

- Extra heating zones

- T-slot platens (110-450 ton)

- Extended daylight with ram spacer

- Eject retract limit switch verification

- Bimetallic barrel & hardened/coated screw

- Ejector on fly

- Free programmable cores

Controls

- Automatic sequence either by codes or free programmable sequence

- 10.5" TFT color display with alpha-numeric keypad

- Actual movement speed & pressure graph display

- 100 mold data storage

- Configurable multilevel password with operator's name

- Graphical hourly production table

- Customized setup menu

- High/low limit display for each adjustable parameter

- 10 diagnose on visualization-analog & digital

- Free I/O assignment

- Change log menu: logs last 100 set points changes with time & date

- Integrated statistical process control (SPC)

- Freely programmable smart outputs

- Over view screen with graphical display of machines functions

- Soft keys for fast access of select menus

- Visual & audible alarm

- Alarm history with date & time log

- Graphical representation of automatic cycle

- Recipe exchange via USB

- Host-PC connection through ethernet

- Remote via modem or internet

- Batch counter with option to turn off the motor

- Mold data/process data/change log saving to external USB device

- Online help

- Function keys with LEDs indicator

Enjector

- Multipoint ejection for uniform force distribution

- Ejector speed & pressure adjustable on screen

- Linear transducer for ejector position

- Pilot operated check valve for ejector

- Multiple pulsating ejector strokes

- Intermediate retract set point

- Ejector stay forward & forward delay timer

Temperature Control

- Meters current display of heating zone

- Heater failure & thermocouple failure detection

- Accurate PID temperature control settable on screen

- Feed throat temperature indication

- Auto heat startup & shutdown

- Heat standby after set number of cycles

- Soak timer for cold start protection

- High/low temperature alarm

- Set & actual temperature data with graph

- Insulated heaters band

- Oil temperature on screen

IN Jection

- Multi stage injection speed & pressure profile

- Multi stage screw speed & manual back pressure control

- Digital setting of screw rpm & digital read out of actual

- Wide choice of injection units with A-B-C screw/barrel combinations

- Comfortable injection unit swivelling

- Switch over from fill to pack based on position or time

- Linear position transducer for accurate injection position

- Injection decompression before/after refilling or both

- Semi-auto purge, cold slung removal & intrusion molding

- Chequered plate below purge area

- Injection start, suck-back & melt decompression-delay timer

- Graphically adjustable alarm bands for injection pressure

- Sliding hopper

- Nozzle contact force by pressure switch